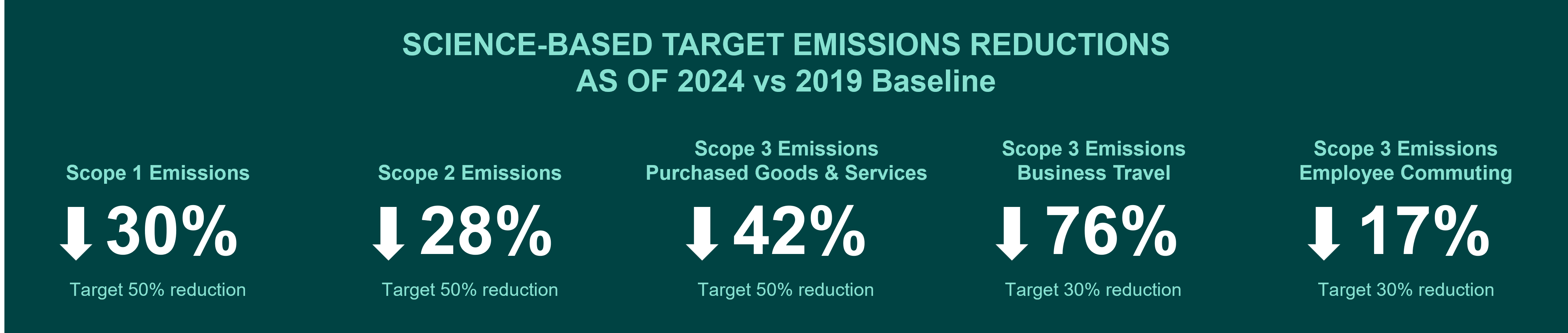

Our 2030 science-based targets represent an important halfway milestone toward our carbon negative goal. And our climate impact data shows that we are well on our way to reaching our 2030 targets. We are also doubling down on direct carbon reductions to meet the urgency of the climate crisis. In other words, we are not slowing down.

2030 Science-Based Targets

Our science-based targets commit to reductions over an 11-year period, with our reduction efforts taking place from 2019 to 2030. After just five years, we have already passed the halfway point toward achieving each target.

2040 Carbon Negative Enterprise

We are ‘all in’ on carbon negative by 2040. How? By avoiding, reducing, and storing more carbon than ever before to reach our bold climate goals. We know what it takes, so we’re doing our part—to help solve the climate crisis.